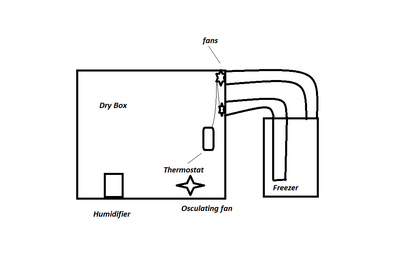

It goes without saying, that there are things to consider here. For example...

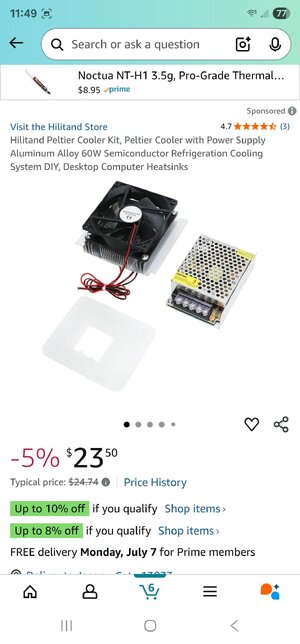

Humidity control

Fresh air turn over

Temperature control

Air flow

So, I will be looking at how all that works together. I make the assumption that the unit pulls in fresh air, but it might not do it frequently enough. So it might require some slow and steady air turnover, using some filtered 1 inch fans installed in opposing sidewalls. Just a thought.

Of all my dries, a total of 4 or 5, the best was 60F and 60 RH. I am looking to improve it with some methodologies I read online. It is a 3 day drawdown from the original amount of moisture introduced in the initial introduction of plant material to the space. If you load and set for 60/60, it will dry out the material to fast. You must slowly pull our moisture over days, to get to 60/60. It's a dance with mold too. If you take too long to stabilize, you run the risk of mold. There are additional methods of target Temp/RH measurements, such as VPD, but I have not researched it as of yet.

In short...meat, cheese, wine, tobacco etc., have 100s of years of experience and knowledge doing the same thing we are doing with cannibas, that is, drying and curing. After you busted your ass growing a fabulous plant, why not finish it correctly with proper drying and curing methodologies. Just saying...lol.

I'll keep trying and sharing. Beats 1000s of dollars on Cannatrol. Just imagine..

Cannatrol is not much different than what us do it yourselfers are doing. If they would just sell it at a fair price of 300-500 dollars, they would be flying off the shelves. But instead I imagine they are collecting dust in a warehouse somewhere in China. Oh well.