Abstract

In an effort to enable the plant, in our case cannabis, to express their top potential both in harvest weight and usable efficiency, cultivators have developed methods of manipulating environmental variables to influence plant growth patterns and behaviors. This process is referred to as crop steering. The basic premise of crop steering is by manipulating environmental parameters such as light intensity, relative humidity, temperature, CO2 levels, EC, pH, water content in the media, and pruning, a cultivator is able to not only accelerate growth patterns but increase yield and quality of a given cultivar. This article aims to lay out the whats, whys, whens, and hows for anyone seeking to adopt this advanced method.

What is Crop Steering?

TL;DR: manipulate the environment to produce Kavorki buds the size of a Volkswagon Bug, brah.

Crop steering is an advanced technique developed specifically for fruiting plants grown in rockwool media. The basic premise is by manipulating environmental factors within the cultivator's control, the cultivator is able to force various growth stages to happen faster, or slower, depending on the cultivator's objectives. The process of doing this fundamentally relies on manipulating the media's EC and water content, and in more advanced applications, can include light intensity, CO2 concentrations, VPD, and aggressive pruning (depending on crop).

Let's focus on the most basic approach: manipulating the media's EC and water content. How do we do this? By controlling the media's dry back cycles. Through granularly controlling when fertigation events occur, a cultivator is able to control the EC of the media by increasing or decreasing the amount of water in the media at a given time. But what does this do? EC has a direct impact on a plant's ability to absorb water. The higher the EC, the harder the plant has to work to intake that water and vis a vis. The impact this has is it can cause varying levels of stress -- specifically drought stress. When talking about cannabis, its specific response to this stressor is to start producing more bracts as it wants to perform its life's purpose of procreation. By experiencing a scarcity of water, the plant produces hormones that tell it time is running out, it better get it's shit in gear and do the deed or it'll die baron and unsuccessful. Conversely, when there is a lower EC, cannabis responds by producing more foliage, growing taller, and focusing less energy on flower production.

In typical crop steering, you have two cycles: vegetative and generative. Vegetative is the foliage production stage -- this is what you will run for the majority of your flowering cycle. Generative is the stress stage. You run this cycle the first two weeks of flower, then again at weeks 5-6 for a typical hybrid 8-10 week finishing cultivar. Sativas and early finishing indicas may require adjustments from this general rule of thumb.

Wait, wait, wait -- you mentioned "flowering cycle." What's with that?

Crop steering for cannabis is typically applied only during the flowering stage. You can run the vegetative schedule during the vegetative stage of growth, but it won't have as substantial impact as you will notice in flowering.

Before we discuss the two cycles and why they are called what they are, what purposes they serve, and why we use them when we do, we need to understand two terms. The first is matric potential. Matric potential is the force roots must overcome to extract water from a given media. The second is osmotic pressure. Osmotic pressure is the force roots must overcome to extract water against a high EC nutrient solution. Roots maintain a certain EC within their structures, and the nutrient solution is at a variable EC. This facilitates water flowing naturally across that osmotic gradient. When EC in the nutrient solution is higher than the EC within the roots, the plant has a more difficult time absorbing water.

By leveraging what we now know, we're able to simulate drought stress. As a consequence, this pushes the plant into a generative state which forces the plant to focus its energy on producing reproductive mass. In essence, this is the core component of crop steering.

Vegetative cycle

Phase of growth where plants establish themselves with more foliage and roots systems. The purpose of driving this stage of growth is to encourage the plant to grow larger with more vigor, with the intention of helping the plant build strong branch structures to support the weight, and ability to feed, the fruits produced at later stages of production. When applied in cannabis, vegetative cycles are applied from day 14 to approximately day 60 of a flower cycle, then again from day 74 through to approximately seven days prior to harvest.

Generative cycle

Phase of growth where plants focus all their energy on reproductive activities. This may entail building flowers, bulking fruits, increasing sugars in fruits, maturing seeds, etc. Depending when this cycle is applied to the plant, you may also see reduction in water consumption coupled with pH swings and climbing EC while the plant develops its fall colors. When applied to cannabis, generative cycles are applied from day one to day 14 of a flower cycle, then again approximately from day 60 to day 74. The reason for this schedule is during initial flower, you want to control stretch and encourage cannabis to set flowers. If you were to run vegetative cycle, the plants will continue producing tons of foliage and potentially delay robust flower setting. Then, we run this cycle again at the bulking stage of flower to drive denser, more prolific bulking. It's not uncommon to see cannabis through a second wave of fresh bracts with bright white pistils during this second cycle, as well as really accelerate towards the finish line.

Along with the generative cycle, growers will typically implement PK boosting during these times, and reduce N. This ensures the plant has the core minerals required for prolific flower production while just enough N to sustain the foliage it has.

How do you "steer" crops?

Alright, let's get down to the meat and potatoes of how all this fits together. Remember this is a hypothetical scenario, and every grow will require the cultivator's attention and involvement so don't stick to this schedule as if it were mandated. We'll assume that the cultivator has a monocrop of clones in rockwool slabs. Our scenario starts one week before changing the light schedule to 12/12 to induce flowering.

Day -7:

The cultivator does a heavy defoliation, taking all large fan leaves and most branches except the top 1/3 nodes. This step is not mandatory, but it helps produce a uniform quality final product. Don't worry, the leaves will grow back. At the same time, the cultivator reduces PPFD by ~30-45% of what they were running. The defoliation is a large stressor, so reducing PPFD gives the plant time to get over the cultivator being an asshole. Lastly, the cultivator mixes in their first PK boost. The idea for this pre-flip PK boost is to ensure the media and plant has the rooting and flower producing minerals in abundance. The fertigation schedule remains what it has been up to this point.

Day 0:

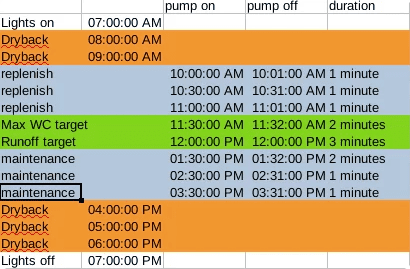

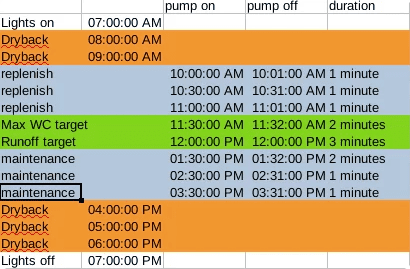

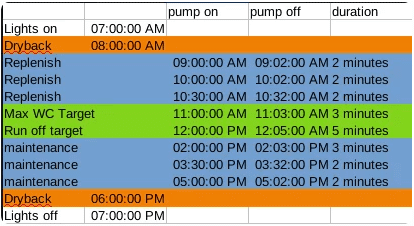

The cultivator reverts back to a vegetative nutrient solution -- no more PK boost needed for now. PPFD is increased by ~10%. Target VPD is set at somewhere between 1.0 - 1.2. This is the start of our first generative cycle, so the cultivator will modify the fertigation schedule to increase more dryback within the media, which increases EC and decreases water availability. The goal is to not allow the media to hit field capacity (maximum water content) until just before mid-day. The next fertigation cycle after hitting max WC, the cultivator will see the first runoff of the day. The reason for doing this is to maintain a high EC level within the media, and not hit equilibrium between the media and the incoming nutrient solution. Remember -- generative cycle is simulated drought stress. This is how the cultivator achieves that. Below is a sample fertigation schedule for the generative cycle.

Day 7:

PPFD is increased by ~10%. VPD is set to a target of 0.8 - 1.0.

Day 14:

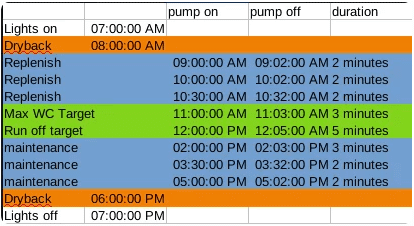

By now the plants are fully recovered, and have set flower. Some pre-flowering will continue for the next seven days, or so, but by now the plants are fully in bloom. VPD is set to a target of 0.8 - 1.2. PPFD is increased ~5%. The cultivator will also shift to somewhere between a full on bloom nutrient solution and vegetative nutrient solution. PK needs are increasing but N is going to be critical given this is also the day that the cultivator changes the fertigation schedule to vegetative cycle. Unlike the generative cycle, the cultivator isn't allowing for such severe dryback, nor as high an EC within the media. Max WC and runoff targets are the same, but the cultivator is now aiming to flush out the excess EC and reach and maintain equilibrium with the incoming nutrient solution for longer durations. Below is a sample schedule to illustrate this.

Day 21:

PPFD is decreased by ~25%. The cultivator does another round of heavy defoliation. This includes pulling anything too far below canopy level that will produce larf or otherwise undesired product. The reason for this is the cultivator is aiming for uniform, consistent product at harvest time. Anything that's not going to produce uniformly will impact final yield and reduce quality overall. VPD is set to a target of 1.0 - 1.2.

Day 28:

PPFD is increased by ~10%. VPD maintained at 1.0 - 1.2. Nutrient solution transitioned to nearly full bloom NPK, though still near-veg N levels.

Day 35:

PPFD is increased by ~10%. VPD maintained at 1.0 - 1.2. Nutrient solution remains the same.

Day 42:

PPFD increased to maximum for this grow cycle. VPD maintained at 1.0 - 1.2. Nutrient solution transitioned to full bloom NPK.

Day 60:

PPFD remains the same. VPD set to 1.2 - 1.4. The cultivator switches back the the generative cycle, and introduces a PK boost.

Day 74:

PPFD decreased by 5%. VPD set to 1.4 - 1.6. The cultivator reverts back to vegetative cycle, and drops the PK boost. The plants are coming into the home stretch now, so the timeline gets a bit less constrained from here going forward. EC of the nutrient solution should start decreasing at this point as well.

Day 81ish:

The cultivator starts monitoring trichomes and pistil generation. EC of the nutrient solution should be around 0.5 at this point. PPFD decreased by ~10%. VPD set to 1.2 - 1.4.

Sometime later:

When the cultivator starts seeing mostly cloudy trichomes with amber trichomes beginning to form, the cultivator will drain the reservoir and refill it with an isotonic solution. This is a is a "flushing" agent (I know, contentious -- we're not here to discuss the validity of this technique). The concept is to maintain the same osmotic pressure as the plant is used to without providing it any nutrients. This will ensure the plant is able to drink water and start to consume any nutritional reserves remaining in its flowers and leaves. The plant converts chlorophyll and other reserves to sugars, which increased the brix content within the product, leading to higher terpene concentrations. The cultivator will run the isotonic solution for five to seven days, then switch to pure water after until the plant is ready for harvest.

What are the benefits of crop steering?

What are the caveats of crop steering?

Why should I care about any of this?

Because it's cool?! No, really this technique is targeted at commercial producers that require consistent harvests within projected timelines. The results can be incredible, and can teach a cultivator a lot more about how plants perform in variable conditions. This technique has the potential to take a cultivator's crop from great to phenomenal if executed well.

Feel free to give any feedback, ask questions, or request additional information! I'll gladly modify/extend this as needed.

Related thread: https://budbuilders.org/threads/drought-stress.141/

In an effort to enable the plant, in our case cannabis, to express their top potential both in harvest weight and usable efficiency, cultivators have developed methods of manipulating environmental variables to influence plant growth patterns and behaviors. This process is referred to as crop steering. The basic premise of crop steering is by manipulating environmental parameters such as light intensity, relative humidity, temperature, CO2 levels, EC, pH, water content in the media, and pruning, a cultivator is able to not only accelerate growth patterns but increase yield and quality of a given cultivar. This article aims to lay out the whats, whys, whens, and hows for anyone seeking to adopt this advanced method.

What is Crop Steering?

TL;DR: manipulate the environment to produce Kavorki buds the size of a Volkswagon Bug, brah.

Crop steering is an advanced technique developed specifically for fruiting plants grown in rockwool media. The basic premise is by manipulating environmental factors within the cultivator's control, the cultivator is able to force various growth stages to happen faster, or slower, depending on the cultivator's objectives. The process of doing this fundamentally relies on manipulating the media's EC and water content, and in more advanced applications, can include light intensity, CO2 concentrations, VPD, and aggressive pruning (depending on crop).

Let's focus on the most basic approach: manipulating the media's EC and water content. How do we do this? By controlling the media's dry back cycles. Through granularly controlling when fertigation events occur, a cultivator is able to control the EC of the media by increasing or decreasing the amount of water in the media at a given time. But what does this do? EC has a direct impact on a plant's ability to absorb water. The higher the EC, the harder the plant has to work to intake that water and vis a vis. The impact this has is it can cause varying levels of stress -- specifically drought stress. When talking about cannabis, its specific response to this stressor is to start producing more bracts as it wants to perform its life's purpose of procreation. By experiencing a scarcity of water, the plant produces hormones that tell it time is running out, it better get it's shit in gear and do the deed or it'll die baron and unsuccessful. Conversely, when there is a lower EC, cannabis responds by producing more foliage, growing taller, and focusing less energy on flower production.

In typical crop steering, you have two cycles: vegetative and generative. Vegetative is the foliage production stage -- this is what you will run for the majority of your flowering cycle. Generative is the stress stage. You run this cycle the first two weeks of flower, then again at weeks 5-6 for a typical hybrid 8-10 week finishing cultivar. Sativas and early finishing indicas may require adjustments from this general rule of thumb.

Wait, wait, wait -- you mentioned "flowering cycle." What's with that?

Crop steering for cannabis is typically applied only during the flowering stage. You can run the vegetative schedule during the vegetative stage of growth, but it won't have as substantial impact as you will notice in flowering.

Before we discuss the two cycles and why they are called what they are, what purposes they serve, and why we use them when we do, we need to understand two terms. The first is matric potential. Matric potential is the force roots must overcome to extract water from a given media. The second is osmotic pressure. Osmotic pressure is the force roots must overcome to extract water against a high EC nutrient solution. Roots maintain a certain EC within their structures, and the nutrient solution is at a variable EC. This facilitates water flowing naturally across that osmotic gradient. When EC in the nutrient solution is higher than the EC within the roots, the plant has a more difficult time absorbing water.

By leveraging what we now know, we're able to simulate drought stress. As a consequence, this pushes the plant into a generative state which forces the plant to focus its energy on producing reproductive mass. In essence, this is the core component of crop steering.

Vegetative cycle

Phase of growth where plants establish themselves with more foliage and roots systems. The purpose of driving this stage of growth is to encourage the plant to grow larger with more vigor, with the intention of helping the plant build strong branch structures to support the weight, and ability to feed, the fruits produced at later stages of production. When applied in cannabis, vegetative cycles are applied from day 14 to approximately day 60 of a flower cycle, then again from day 74 through to approximately seven days prior to harvest.

Generative cycle

Phase of growth where plants focus all their energy on reproductive activities. This may entail building flowers, bulking fruits, increasing sugars in fruits, maturing seeds, etc. Depending when this cycle is applied to the plant, you may also see reduction in water consumption coupled with pH swings and climbing EC while the plant develops its fall colors. When applied to cannabis, generative cycles are applied from day one to day 14 of a flower cycle, then again approximately from day 60 to day 74. The reason for this schedule is during initial flower, you want to control stretch and encourage cannabis to set flowers. If you were to run vegetative cycle, the plants will continue producing tons of foliage and potentially delay robust flower setting. Then, we run this cycle again at the bulking stage of flower to drive denser, more prolific bulking. It's not uncommon to see cannabis through a second wave of fresh bracts with bright white pistils during this second cycle, as well as really accelerate towards the finish line.

Along with the generative cycle, growers will typically implement PK boosting during these times, and reduce N. This ensures the plant has the core minerals required for prolific flower production while just enough N to sustain the foliage it has.

How do you "steer" crops?

Alright, let's get down to the meat and potatoes of how all this fits together. Remember this is a hypothetical scenario, and every grow will require the cultivator's attention and involvement so don't stick to this schedule as if it were mandated. We'll assume that the cultivator has a monocrop of clones in rockwool slabs. Our scenario starts one week before changing the light schedule to 12/12 to induce flowering.

Day -7:

The cultivator does a heavy defoliation, taking all large fan leaves and most branches except the top 1/3 nodes. This step is not mandatory, but it helps produce a uniform quality final product. Don't worry, the leaves will grow back. At the same time, the cultivator reduces PPFD by ~30-45% of what they were running. The defoliation is a large stressor, so reducing PPFD gives the plant time to get over the cultivator being an asshole. Lastly, the cultivator mixes in their first PK boost. The idea for this pre-flip PK boost is to ensure the media and plant has the rooting and flower producing minerals in abundance. The fertigation schedule remains what it has been up to this point.

Day 0:

The cultivator reverts back to a vegetative nutrient solution -- no more PK boost needed for now. PPFD is increased by ~10%. Target VPD is set at somewhere between 1.0 - 1.2. This is the start of our first generative cycle, so the cultivator will modify the fertigation schedule to increase more dryback within the media, which increases EC and decreases water availability. The goal is to not allow the media to hit field capacity (maximum water content) until just before mid-day. The next fertigation cycle after hitting max WC, the cultivator will see the first runoff of the day. The reason for doing this is to maintain a high EC level within the media, and not hit equilibrium between the media and the incoming nutrient solution. Remember -- generative cycle is simulated drought stress. This is how the cultivator achieves that. Below is a sample fertigation schedule for the generative cycle.

Day 7:

PPFD is increased by ~10%. VPD is set to a target of 0.8 - 1.0.

Day 14:

By now the plants are fully recovered, and have set flower. Some pre-flowering will continue for the next seven days, or so, but by now the plants are fully in bloom. VPD is set to a target of 0.8 - 1.2. PPFD is increased ~5%. The cultivator will also shift to somewhere between a full on bloom nutrient solution and vegetative nutrient solution. PK needs are increasing but N is going to be critical given this is also the day that the cultivator changes the fertigation schedule to vegetative cycle. Unlike the generative cycle, the cultivator isn't allowing for such severe dryback, nor as high an EC within the media. Max WC and runoff targets are the same, but the cultivator is now aiming to flush out the excess EC and reach and maintain equilibrium with the incoming nutrient solution for longer durations. Below is a sample schedule to illustrate this.

Day 21:

PPFD is decreased by ~25%. The cultivator does another round of heavy defoliation. This includes pulling anything too far below canopy level that will produce larf or otherwise undesired product. The reason for this is the cultivator is aiming for uniform, consistent product at harvest time. Anything that's not going to produce uniformly will impact final yield and reduce quality overall. VPD is set to a target of 1.0 - 1.2.

Day 28:

PPFD is increased by ~10%. VPD maintained at 1.0 - 1.2. Nutrient solution transitioned to nearly full bloom NPK, though still near-veg N levels.

Day 35:

PPFD is increased by ~10%. VPD maintained at 1.0 - 1.2. Nutrient solution remains the same.

Day 42:

PPFD increased to maximum for this grow cycle. VPD maintained at 1.0 - 1.2. Nutrient solution transitioned to full bloom NPK.

Day 60:

PPFD remains the same. VPD set to 1.2 - 1.4. The cultivator switches back the the generative cycle, and introduces a PK boost.

Day 74:

PPFD decreased by 5%. VPD set to 1.4 - 1.6. The cultivator reverts back to vegetative cycle, and drops the PK boost. The plants are coming into the home stretch now, so the timeline gets a bit less constrained from here going forward. EC of the nutrient solution should start decreasing at this point as well.

Day 81ish:

The cultivator starts monitoring trichomes and pistil generation. EC of the nutrient solution should be around 0.5 at this point. PPFD decreased by ~10%. VPD set to 1.2 - 1.4.

Sometime later:

When the cultivator starts seeing mostly cloudy trichomes with amber trichomes beginning to form, the cultivator will drain the reservoir and refill it with an isotonic solution. This is a is a "flushing" agent (I know, contentious -- we're not here to discuss the validity of this technique). The concept is to maintain the same osmotic pressure as the plant is used to without providing it any nutrients. This will ensure the plant is able to drink water and start to consume any nutritional reserves remaining in its flowers and leaves. The plant converts chlorophyll and other reserves to sugars, which increased the brix content within the product, leading to higher terpene concentrations. The cultivator will run the isotonic solution for five to seven days, then switch to pure water after until the plant is ready for harvest.

What are the benefits of crop steering?

- More robust, vigorous growth

- Less waste

- More uniform, consistent harvests

- More predictable timelines and results

- Easier harvest procedures

- Cultivator is able to get ahead of problems before they become a problem

What are the caveats of crop steering?

- Higher risk of plant damage or death due to equipment failure

- Requires much higher attention to detail

- Requires more involvement from the cultivator

- Incredibly difficult to do without controllers or sensors to provide the cultivator data, and granular control, of media and environmental conditions

- Not a novice-friendly technique

- Only applies to rockwool, can be performed in coco to an extent. Not applicable in other hydro mediums, nor in soil(less).

Why should I care about any of this?

Because it's cool?! No, really this technique is targeted at commercial producers that require consistent harvests within projected timelines. The results can be incredible, and can teach a cultivator a lot more about how plants perform in variable conditions. This technique has the potential to take a cultivator's crop from great to phenomenal if executed well.

Feel free to give any feedback, ask questions, or request additional information! I'll gladly modify/extend this as needed.

Related thread: https://budbuilders.org/threads/drought-stress.141/