gotta drill?

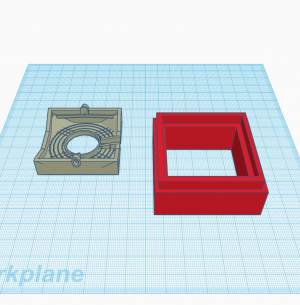

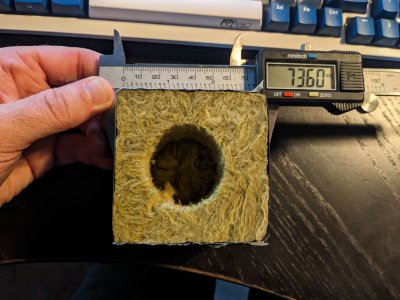

I'm not sure how big they are. They can be made larger by design or drilled out.

I think the line holes are for 1/4" tubing but again, not sure.

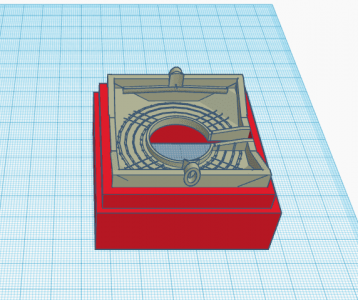

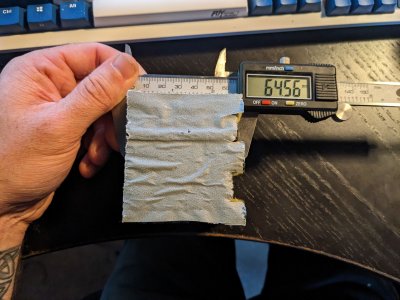

This design is supposed to be for 4x4 blocks so once you start to resize, those holes also resize and since I don't know their original diameter, I can't say what the resized diameter will be until later. Whoever designed this left out those details so there's some reverse engineering to some of these designs

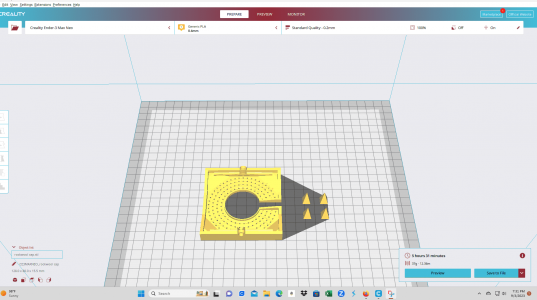

I'm making a 50mmx50mm test print of this right now. If it looks good and clean I'll resize to 3" and go from there.

Sometimes with stuff like this and those feeder line holes, I have to print it first and see what the actual size is after printing. From there I can go back to the drawings and resize those holes to exact specs. I had to do that for my drip rings on both the feeder line hole, it's depth, and the dripper holes made larger.

www.thingiverse.com

www.thingiverse.com