Note to self...

When making a drip irrigation ring, it's a good idea to make sure the "fill in holes" box in the slicer settings is not checked.

So yeah..My printer just spent the last 23 hours making a solid drip ring

So after that initial fuck up this project is coming along and is one I'm pretty excited about. Kinda taking drip irrigation hydro old school. Very old school. Like ancient Rome aquaduct old school

This will be an air lift powered irrigation system and rather than a drip ring, I'm working on an aquaduct really.

I downloaded a pretty good airlift ring design off Cults and took it into my garage on tinkercad.

From there, I resized and took the top off the ring to make it a channel. That's gonna make it super ez to keep clean.

After the initial print I liked what I got but still needs work. I resized it again, increased dripper holes to 3.5mm diameter and beefed it up around the bends.

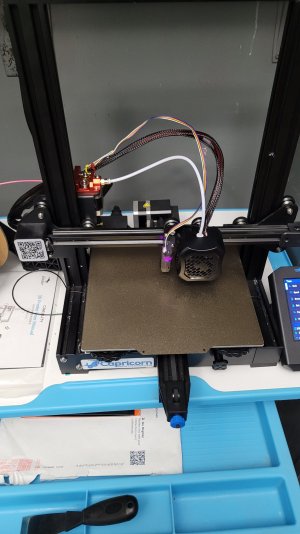

Final version is on the printer now and should be done in about 9 hours.

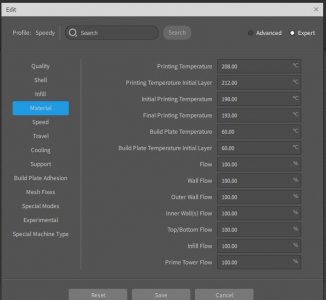

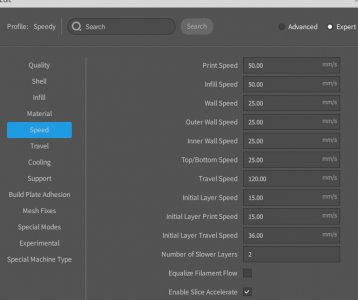

I'm using food grade PETG filament, 240 at the nozzle, 70 on the bed, infill density at 100%, and speed at 100%

The fuck up is on the right. I was wondering why an 8 hour print was taking a whole day and it never turned into a channel so I cut if off at 60% to figure out what happened. I knew it was in the slicer somewhere after doing a preview check so after some searching I realized there's a little check box that says "Fill in holes" and it was checked

View attachment 15782

View attachment 15782

An almost usable prototype. Final version is printing now

View attachment 15783

View attachment 15783