How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature currently requires accessing the site using the built-in Safari browser.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

3D printers and the things growers and stoners can make with them

- Thread starter Bandit420

- Start date

- Joined

- Apr 19, 2023

- Messages

- 6,631

- Reaction score

- 33,771

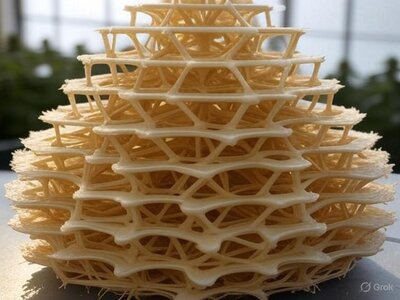

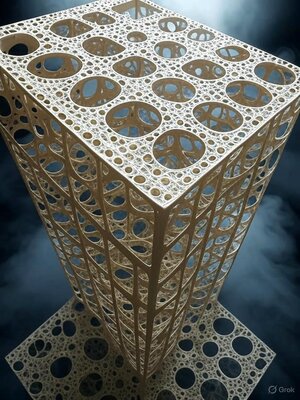

those are made with a resin printer, not a filament printer.. different beasts.. they're cool though!!!

they pull the plastic up from a liquid bath of resin, like magic!!! ...

Observer

Quantum Yield Engineer

- Joined

- May 11, 2023

- Messages

- 8,330

- Reaction score

- 20,313

Ooothose are made with a resin printer, not a filament printer.. different beasts.. they're cool though!!!

they pull the plastic up from a liquid bath of resin, like magic!!! ...

That's cool, looks a lot pricier lol

Zen_seeker

POTM Winner 🏆

- Joined

- Apr 16, 2023

- Messages

- 6,579

- Reaction score

- 25,344

Saw a pegboard display that I can put beside the sink. Son said it will take half a spool but should be good.

He’s made a few attachments as well as a bunch of hooks.

Think he said 14hrs.

=-=-=-=-=-=-=-=-=

I found a good AMS unit that’s supposed to be better than the original. He printed everything but the two motors and a few tubes. Saved $200. He’s happy.

Now he’s got to figure out how to get it all back into the tent.

=-=-=-=-=-=-=-=-

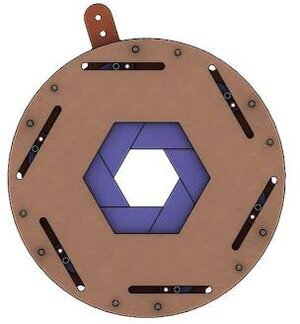

He printed this the other day but he doesn’t like it. He has lots of magnets for his projects but the lid just seems too flimsy. He likes mine better but needs a lighter compartment.

He’s made a few attachments as well as a bunch of hooks.

Think he said 14hrs.

=-=-=-=-=-=-=-=-=

I found a good AMS unit that’s supposed to be better than the original. He printed everything but the two motors and a few tubes. Saved $200. He’s happy.

Now he’s got to figure out how to get it all back into the tent.

=-=-=-=-=-=-=-=-

He printed this the other day but he doesn’t like it. He has lots of magnets for his projects but the lid just seems too flimsy. He likes mine better but needs a lighter compartment.

Observer

Quantum Yield Engineer

- Joined

- May 11, 2023

- Messages

- 8,330

- Reaction score

- 20,313

Little bigger neodymium magnets?Saw a pegboard display that I can put beside the sink. Son said it will take half a spool but should be good.View attachment 103113

He’s made a few attachments as well as a bunch of hooks.View attachment 103114

Think he said 14hrs. View attachment 103110

=-=-=-=-=-=-=-=-=

I found a good AMS unit that’s supposed to be better than the original. He printed everything but the two motors and a few tubes. Saved $200. He’s happy.View attachment 103112

Now he’s got to figure out how to get it all back into the tent.

=-=-=-=-=-=-=-=-

He printed this the other day but he doesn’t like it. He has lots of magnets for his projects but the lid just seems too flimsy. He likes mine better but needs a lighter compartment. View attachment 103115

Zen_seeker

POTM Winner 🏆

- Joined

- Apr 16, 2023

- Messages

- 6,579

- Reaction score

- 25,344

Not enough. Needs a lip, track or twist added. Like the Lobo mouth piece.Little bigger neodymium magnets?

Zen_seeker

POTM Winner 🏆

- Joined

- Apr 16, 2023

- Messages

- 6,579

- Reaction score

- 25,344

Son made one with magnets. Not a very tight/strong fit though. How’s yours?

- Joined

- Apr 19, 2023

- Messages

- 6,631

- Reaction score

- 33,771

Saw a pegboard display that I can put beside the sink. Son said it will take half a spool but should be good.View attachment 103113

He’s made a few attachments as well as a bunch of hooks.View attachment 103114

Think he said 14hrs. View attachment 103110

=-=-=-=-=-=-=-=-=

I found a good AMS unit that’s supposed to be better than the original. He printed everything but the two motors and a few tubes. Saved $200. He’s happy.View attachment 103112

Now he’s got to figure out how to get it all back into the tent.

=-=-=-=-=-=-=-=-

He printed this the other day but he doesn’t like it. He has lots of magnets for his projects but the lid just seems too flimsy. He likes mine better but needs a lighter compartment. View attachment 103115

i designed very similar hooks to go under my cabinet doors to hang fresh pasta from!! great minds thinkin alike..

other goofy kitchen stuff i made..

sponge holder..

under cabinet tong rack hooks...

egg sheller...

Son made one with magnets. Not a very tight/strong fit though. How’s yours?

a little too tight, water tight.. don't know how deep for diving or anything but i dunked it and shook it around under water.. the lid ain't falling off.. it takes some muscle to open it.

Zen_seeker

POTM Winner 🏆

- Joined

- Apr 16, 2023

- Messages

- 6,579

- Reaction score

- 25,344

@Stoneyluv I’m sort of doing the same thing. But saving links more than asking that I print them, for now.

Lots of brackets and building tools. Trying to avoid just the cool ideas with no practical purpose.

I’ve never seen an egg sheller before.

Still got two hours left on the pegboard display.

A better shot of the AMS v2.0

Here are the two motors and tubes he had to buy. Most of what I print or get him to print is black.

More things I’d like to do but it will have to wait until I can mod the files and make my own.

Lots of brackets and building tools. Trying to avoid just the cool ideas with no practical purpose.

I’ve never seen an egg sheller before.

Still got two hours left on the pegboard display.

A better shot of the AMS v2.0

Here are the two motors and tubes he had to buy. Most of what I print or get him to print is black.

More things I’d like to do but it will have to wait until I can mod the files and make my own.

Zen_seeker

POTM Winner 🏆

- Joined

- Apr 16, 2023

- Messages

- 6,579

- Reaction score

- 25,344

Observer

Quantum Yield Engineer

- Joined

- May 11, 2023

- Messages

- 8,330

- Reaction score

- 20,313

Observer

Quantum Yield Engineer

- Joined

- May 11, 2023

- Messages

- 8,330

- Reaction score

- 20,313

Treadmill modded into giant 3D printer with an endless print bed size — taking 3D print sizing to the extreme

The possibilities are now literally endless.

Observer

Quantum Yield Engineer

- Joined

- May 11, 2023

- Messages

- 8,330

- Reaction score

- 20,313

Take the covers off?Son was able to resize and change supports so it finally printed properly. Testing two now with good results so far.

View attachment 103572View attachment 103573View attachment 103574

They just collect dust and interfere with the windflow

Zen_seeker

POTM Winner 🏆

- Joined

- Apr 16, 2023

- Messages

- 6,579

- Reaction score

- 25,344

I’d hit one, break it, nock the pole over, tear the tent, fall back off my stool, fall into a coughing fit, have Willow on my chest wondering what game I’m playing, while my son is laughing in the doorway. I’ll just leave it on.Take the covers off?

They just collect dust and interfere with the windflow

Seriously it’s more of an ocd thing. Looks broken off.

- Joined

- Apr 19, 2023

- Messages

- 6,631

- Reaction score

- 33,771

I’d hit one, break it, nock the pole over, tear the tent, fall back off my stool, fall into a coughing fit, have Willow on my chest wondering what game I’m playing, while my son is laughing in the doorway. I’ll just leave it on.

Seriously it’s more of an ocd thing. Looks broken off.

this made me laugh.. i'd need to print a bandaid holder next to it if i took the shrouds off!!! haha

Zen_seeker

POTM Winner 🏆

- Joined

- Apr 16, 2023

- Messages

- 6,579

- Reaction score

- 25,344

Any of you experts know why this occurs and how to stop it?

It printed in this vertical position with tree supports.

It’s two parts that are well designed and fit together perfectly.

This is a prototype that will be used for testing before being printed in PETG. I’d like to solve this error before making the final print.

TIA

It printed in this vertical position with tree supports.

It’s two parts that are well designed and fit together perfectly.

This is a prototype that will be used for testing before being printed in PETG. I’d like to solve this error before making the final print.

TIA

- Joined

- Apr 15, 2023

- Messages

- 3,881

- Reaction score

- 24,915

Any of you experts know why this occurs and how to stop it?

View attachment 106739

View attachment 106740

View attachment 106741

It printed in this vertical position with tree supports.

View attachment 106742

It’s two parts that are well designed and fit together perfectly.

View attachment 106743

This is a prototype that will be used for testing before being printed in PETG. I’d like to solve this error before making the final print.

TIA

I'd print it again but use a different filament.

I'm betting it's in the filament itself, maybe a thin spot in the line, moisture, air bubbles in the plastic etc.

If it does the same thing with a different filament then you know it's not the filament and it's something in the slicer settings that did it.

The rest of the print looks good though so I'm thinking it was just a bad stretch of filament in the spool

Zen_seeker

POTM Winner 🏆

- Joined

- Apr 16, 2023

- Messages

- 6,579

- Reaction score

- 25,344

I’m hoping it’s the type since PETG is recommended. But he’s had this happen in other prints. Might be the brand he’s buying.I'd print it again but use a different filament.

I'm betting it's in the filament itself, maybe a thin spot in the line, moisture, air bubbles in the plastic etc.

If it does the same thing with a different filament then you know it's not the filament and it's something in the slicer settings that did it.

The rest of the print looks good though so I'm thinking it was just a bad stretch of filament in the spool

I want to buy a Dark Earth PETG spool to do this in. Any recommendations?

He’s mentioned before that splicing was needed and using STL files can require reworking. Not always successfully.

He’s on the midnight shift so I’ll talk to him when he’s up tonight.

Thanks Bandit

- Joined

- Apr 15, 2023

- Messages

- 3,881

- Reaction score

- 24,915

I’m hoping it’s the type since PETG is recommended. But he’s had this happen in other prints. Might be the brand he’s buying.

I want to buy a Dark Earth PETG spool to do this in. Any recommendations?

He’s mentioned before that splicing was needed and using STL files can require reworking. Not always successfully.

He’s on the midnight shift so I’ll talk to him when he’s up tonight.

Thanks Bandit

I doubt my recs would be any good man but I'll toss 'em out to ya.

My first thing is usually color then price. I've hit and missed on a lot of spools.

I can vouch for Overture, Creality, and Flashforge.

Sunlu has been good but also a few bad spools, like maybe 4 bad spools out of 30 used.

Brands I avoid due to horrible experiences are Shengtian (gold metal), and Yousu.

Metal colors, bi and tri-color, and silks are super hit and miss for me. I've learned to shop for those in the small .5KG spools

When I find a reliable one I buy it in different colors when it's on sale. Like right now most of my supply is Overture and Sunlu. My spool of food grade is from Carbon Brand and it's very good but pricey.

Prime Day is coming so that's a time to buy in the USA but not sure for Y'all up north.

Another on my radar is PCTG for prints requiring durability and some UV resistance. It's supposed to be like a super strength PETG but it's almost $40/2KG spool in the USA.

I also wanna try using a .2 nozzle for finer print results.

Last edited:

Zen_seeker

POTM Winner 🏆

- Joined

- Apr 16, 2023

- Messages

- 6,579

- Reaction score

- 25,344

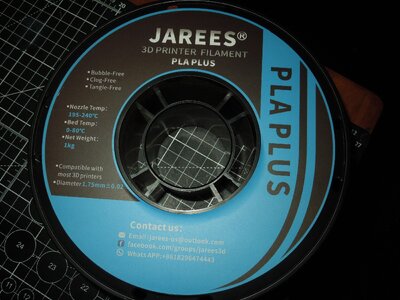

He’s aware of some of these brands. He’s also buying by color first and price second. He’s got a few good ones though. Still learning what works best for him/us. He has a PETG and PLA+ but in black as we use that colour the most. But for somewhat obvious reasons I don’t want another black chassis.I doubt my recs would be any good man but I'll toss 'em out to ya.

My first thing is usually color then price. I've hit and missed on a lot of spools.

I can vouch for Overture, Creality, and Flashforge.

Sunlu has been good but also a few bad spools, like maybe 4 bad spools out of 30 used.

Brands I avoid due to horrible experiences are Shengtian (gold metal), and Yousu.

Metal colors, bi and tri-color, and silks are super hit and miss for me. I've learned to shop for those in the small .5KG spools

When I find a reliable one I buy it in different colors when it's on sale. Like right now most of my supply is Overture and Sunlu. My spool of food grade is from Carbon Brand and it's very good but pricey.

Prime Day is coming so that's a time to buy in the USA but not sure for Y'all up north.

Another on my radar is PCTG for prints requiring durability and some UV resistance. It's supposed to be like a super strength PETG but it's almost $40/2KG spool in the USA.

I also wanna try using a .2 nozzle for finer print results.

First chassis broke while dry fitting the buffer tube.

I was able to make the first wrong chassis model work with a dremel tool. Need a few new bolts now as the original are too short.

Dry fit. Nothings bolted together. Everything is spare parts I no longer used other than the scope.

Printing the new chassis today.

Zen_seeker

POTM Winner 🏆

- Joined

- Apr 16, 2023

- Messages

- 6,579

- Reaction score

- 25,344

Yes, but not for anything that needed more strength. We use black the most and he only had PLA+ and PETG in black.Zen, have you tried pla+ filament? i find it stronger than petg but easy on the printer like pla. pretty much all i use anymore. i like the elegoo rapid series.

Even though it’s only a .22LR when people see a black rifle they jump to the assault rifle media BS. So these days I do a tan or FDE color.

By fluke we ordered the PLA+ Wood color last night with early morning free delivery. We like the Elegoo brand so far. Arrived by 7am. Already started the 8hr print.

Thanks for the feedback guys. If any of you have tried the CF versions let me know. He’s got a .2 nozzle but thinks he’d need a diamond one for CF.

This is the setup we are testing to dampen vibrations and find the best orientation before stuffing back into the tent. He’s also printed a bunch of spool holders and stuff already moved into the side tent section.

I found the multi color stand he was able to print but he had to buy the two motors. Saved him a couple hundred $.

Last edited:

Zen_seeker

POTM Winner 🏆

- Joined

- Apr 16, 2023

- Messages

- 6,579

- Reaction score

- 25,344

Things went better with the PLA+. We used it as soon as it arrived and it was vacuum sealed. So either the better quality and type or maybe no humidity issues helped solve the artifact issues.

I never knew how these things printed or supported the structures so took a few pics as I waited so any other unfamiliar people can see it.

Receiver

Hand guard

Dry fit but new bolts are needed to finish the assembly. Can’t find a 12-24 1” hex head screw which holds it all together. Firearms always seem to use odd threads/sizes.

Once I get the right bolt I can use this JB Weld plastic bonder to permanently join the guard and receiver. I need to compress it when screwing into the rifle mount. Then I can clean off any excess.

So the builds almost done but any testing or sighting in will have to wait. I miss the old hardware store that carried every type of nut, bolt, screw or fastener. It got bought out by Home Depot years ago.

I never knew how these things printed or supported the structures so took a few pics as I waited so any other unfamiliar people can see it.

Receiver

Hand guard

Dry fit but new bolts are needed to finish the assembly. Can’t find a 12-24 1” hex head screw which holds it all together. Firearms always seem to use odd threads/sizes.

Once I get the right bolt I can use this JB Weld plastic bonder to permanently join the guard and receiver. I need to compress it when screwing into the rifle mount. Then I can clean off any excess.

So the builds almost done but any testing or sighting in will have to wait. I miss the old hardware store that carried every type of nut, bolt, screw or fastener. It got bought out by Home Depot years ago.

- Joined

- Apr 19, 2023

- Messages

- 6,631

- Reaction score

- 33,771

it was vacuum sealed. So either the better quality and type or maybe no humidity issues helped solve the artifact issues.

you mean you've bought filament that wasn't vacuum wrapped? if so what brand? so i can stay away!! haha

Zen_seeker

POTM Winner 🏆

- Joined

- Apr 16, 2023

- Messages

- 6,579

- Reaction score

- 25,344

No… I mean our main floor was 85% humidity for a week. Since PLA/PLA+ holds water I figure that using a fresh spool that just arrived in the last 12hrs might do better and have less artifacts or errors.you mean you've bought filament that wasn't vacuum wrapped? if so what brand? so i can stay away!! haha

Regardless it printed great this time. Just need a 1/4” longer mounting bolt to connect the chassis now.

- Joined

- Apr 19, 2023

- Messages

- 6,631

- Reaction score

- 33,771

No… I mean our main floor was 85% humidity for a week. Since PLA/PLA+ holds water I figure that using a fresh spool that just arrived in the last 12hrs might do better and have less artifacts or errors.

Regardless it printed great this time. Just need a 1/4” longer mounting bolt to connect the chassis now.

alright so this is bizzare, just as we're discussing bad filament... today i wanted to print some new shower door handle washers for the current worn ones in place that wobble.

so i grabbed this spool off of my shelf...

and for my printer it loads easier if i trim the end of the used filament first. well i noticed it was brittle, it was almost a full roll... clear color. i kept unspooling it and it was still brittle four or five layers in... heres a video of what it was like.. listen to cracking..

buyer beware!!! it only happened to the clear though. petg clear was perfectly fine just next to it on the same shelf... food for thought.

i had some PETG in clear on hand so that came to rescue and hopefully there will be no more wobble and i will be the hero!!!! hahaha

Zen_seeker

POTM Winner 🏆

- Joined

- Apr 16, 2023

- Messages

- 6,579

- Reaction score

- 25,344

Small world. The pull out shower handle in the basement tub broke last week. I thought about printing a new one but couldn’t find anything that already existed.alright so this is bizzare, just as we're discussing bad filament... today i wanted to print some new shower door handle washers for the current worn ones in place that wobble.

so i grabbed this spool off of my shelf...

View attachment 107203

and for my printer it loads easier if i trim the end of the used filament first. well i noticed it was brittle, it was almost a full roll... clear color. i kept unspooling it and it was still brittle four or five layers in... heres a video of what it was like.. listen to cracking..

buyer beware!!! it only happened to the clear though. petg clear was perfectly fine just next to it on the same shelf... food for thought.

i had some PETG in clear on hand so that came to rescue and hopefully there will be no more wobble and i will be the hero!!!! hahaha

View attachment 107202

Stores wanted from $14 to $40 for a replacement. I got the $14 one.

Unfortunately with all the commotion over the holiday weekend I’ve miss placed the chassis bolt I had. Hoping it’s in the cars cup holder. I was returning things as well as looking for the shower knob that day.

The replacement trigger I printed turned out perfect. Unfortunately it’s for a slightly different model than mine so a pin is slightly out of place. Can’t use it. Trigger group needed cleaning anyway.

We had already ordered the wood coloured PLA+ so it was great when you guys noted it would probably be the better choice. But I’ve noticed the hand guard might be flexing a bit. Can’t really tell without the “hand guard adapter screw”. So I asked the AI about it. Sounds like I should order PETG for a few reasons. UV protection as I don’t shoot in the dark. A more rigid chassis as flex will throw things off or cause connection fatigue. Stronger material.

It would be great if I could find PETG in the same wood colour but that’s doubtful. I’d like the final chassis in PETG but things like the trigger I’d prefer in PLA+.

Ah well, live and learn.

Zen_seeker

POTM Winner 🏆

- Joined

- Apr 16, 2023

- Messages

- 6,579

- Reaction score

- 25,344

- Joined

- Apr 15, 2023

- Messages

- 9,404

- Reaction score

- 47,931

Guess who got a prusa mk3

This guy

This guy