- Joined

- Apr 15, 2023

- Messages

- 3,684

- Reaction score

- 23,900

I'll start it off by saying if I and all my ADD, blurred vision, stoned and aging mind can figure out this stuff then I know you can to. At first it's overwhelming but then I realized it's all simple really once you understand a few things and go thru some trial and error. I'm fairly new to all of it but getting better with each new project.

My printer is a Creality Ender 3 Max Neo and I can make anything sized up to about 11"x 11"x 12"

I use the Creality Slicer program which is the same as Cura. I also have Creality Print on my PC but have not got into using it much

To make things that do not exist or to resize downloads of prints others have made I use Tinkercad which requires an account set up. Using it is free

www.tinkercad.com

www.tinkercad.com

To download files of existing things, I use Cults and Thingiverse.

cults3d.com

cults3d.com

www.thingiverse.com

Basically my process is download a file and put it on my desktop. From there I open up Tinkercad, start a new project, and hit the import button. It will import the download to my Tinkercad profile and from there I can resize it to exactly what I want.

www.thingiverse.com

Basically my process is download a file and put it on my desktop. From there I open up Tinkercad, start a new project, and hit the import button. It will import the download to my Tinkercad profile and from there I can resize it to exactly what I want.

This link is to my Tinkercad account where you can find all the things I've created and made public for anybody to take and remix or download as is to your computer.

www.tinkercad.com

www.tinkercad.com

Some of the things I've either designed from nothing, just working with shapes to make things, or taking a download and remixing it to the specs I need...

Vertical germinators

Seedling support stakes for stretchy sprouts

SCROG hooks

Ratchet rope hanger organizers

Inkbird CO2 monitor wall mount cradle

Watering can

View attachment IMG_4360.MOV

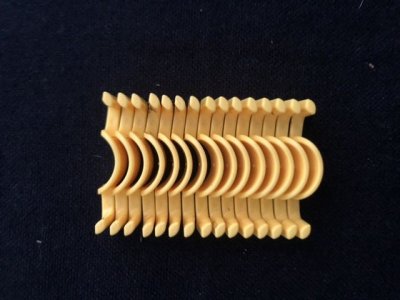

Netcups

View attachment IMG_4336.MOV

To be continued....

My printer is a Creality Ender 3 Max Neo and I can make anything sized up to about 11"x 11"x 12"

I use the Creality Slicer program which is the same as Cura. I also have Creality Print on my PC but have not got into using it much

To make things that do not exist or to resize downloads of prints others have made I use Tinkercad which requires an account set up. Using it is free

3D Design - Tinkercad

3D design is the first step in bringing your ideas to life. Start your journey to change how the world is designed and made today.

To download files of existing things, I use Cults and Thingiverse.

Cults・Download free 3D printer models・STL, OBJ, 3MF, CAD

World’s leading independent website for 3D printer files・Download the best objects for 3D printing・Share your designs on Cults3D the biggest DIY community.

Thingiverse - Digital Designs for Physical Objects

Download millions of 3D models and files for your 3D printer, laser cutter, or CNC. From custom parts to unique designs, you can find them on Thingive

This link is to my Tinkercad account where you can find all the things I've created and made public for anybody to take and remix or download as is to your computer.

Tinkercad

Tinkercad is a free, easy-to-use app for 3D design, electronics, and coding.

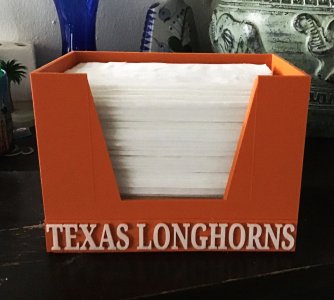

Some of the things I've either designed from nothing, just working with shapes to make things, or taking a download and remixing it to the specs I need...

Vertical germinators

Seedling support stakes for stretchy sprouts

SCROG hooks

Ratchet rope hanger organizers

Inkbird CO2 monitor wall mount cradle

Watering can

View attachment IMG_4360.MOV

Netcups

View attachment IMG_4336.MOV

To be continued....