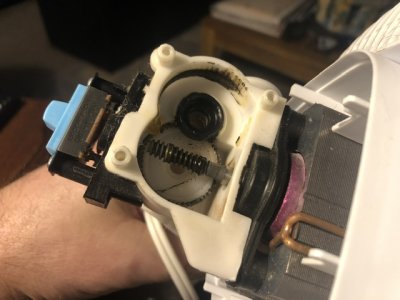

This is the same “designed to fail” worm drive that modern mixers use.

The worm gear is metal and the drive gear is soft plastic. When the fan oscillating is prevented the metal gear heats and melts/gouges it the middle of the drive gear.

As this removes material and leaves a concave hollow in the middle of the plastic gear the metal worm gear no long can reach the teeth to oscillate the fan.

This newer plastic and design doesn’t help with repairs. Filling the void in the middle of the gear is extremely difficult to get right. Then you need to fix the gears teeth.

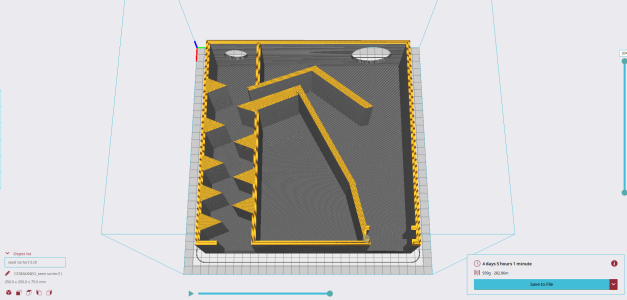

A drop in replacement would be fine. About 15 minutes total work. The design is common but size and gear probably change.

Should be worth it if ACI is the most popular brand but mines just a $25 clip on.

Anyone else take these apart to see if fixable?

@tobh @Rootsruler

JB Weld has worked in the past but haven’t tried it on this softer plastic. Not confident it would last.

View attachment 28936View attachment 28937View attachment 28938