Zen_seeker

POTM Winner 🏆

- Joined

- Apr 16, 2023

- Messages

- 6,443

- Reaction score

- 24,891

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature currently requires accessing the site using the built-in Safari browser.

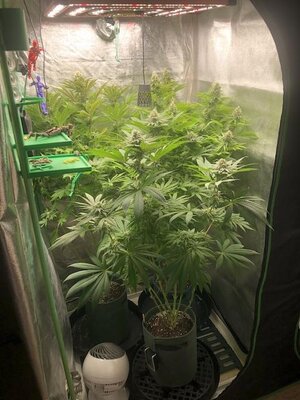

Hey, are you meaning 11 on 13 off? I've done a whole flowering cycle on an 11 on 13 off and I won't do it again. smaller flimsy buds. I've gone the other way too 13 on 11 off and 14 on 10 off at the end but I was using far reds at lights out to take advantage of the Emerson effect. I finished in 9 weeks as opposed to my 11 weeks now but I may try that light cycle again to get a better understanding of it. Giving them more light in flower is better than giving them less imho.I bumped the light to a 11/13 schedule weeks ago. Have around 30+ days to go so thinking about bumping to 10/14. Only tried this once before and don’t recall the results.

Lights still at 70% but I’m considering 60% in the near future. Might help with the taller plants and slow the fading.

Decisions decisions…

Quick chat with AI says my plan to reduce to 10/14 should be best around 21 days before expected harvest with light reduction to 60% the last two weeks.

Thanks for the feedback Pipe.Hey, are you meaning 11 on 13 off? I've done a whole flowering cycle on an 11 on 13 off and I won't do it again. smaller flimsy buds. I've gone the other way too 13 on 11 off and 14 on 10 off at the end but I was using far reds at lights out to take advantage of the Emerson effect. I finished in 9 weeks as opposed to my 11 weeks now but I may try that light cycle again to get a better understanding of it. Giving them more light in flower is better than giving them less imho.

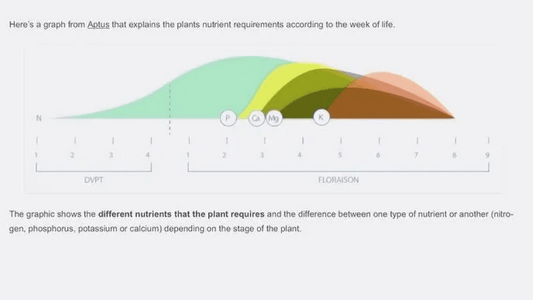

Yes on both, I start dropping my lights as I drop my feed. Ideally when your feed is at max then so is your light and as feed drops lights drop. ....but you can increase your day lights on as you drop your intensity keeping the same DLI through your grow. You can increase lights on at the end to 18 hrs while decreasing the intensity to 60% ish....there is a formula to keep the same DLI........I again use this graph as a guide to increasing and decreasing lights and food but I extend it to suit my 11 weeks of flowering and start turning lights down around week 9 for me.Thanks for the feedback Pipe.

Oh, I was under the impression it helps with bulking up the flowers and pushes the plant into hurrying as winters coming.

Switching back to 12/12 isn’t too hard. Just need to muck with the mechanical timer a bit. You recommending I go back to 12/12?

What about reducing the light to 60% the last two or three weeks?

Hey, looking good, plants look nice, Do you have your stash of weed in the totes? I'd be good for a year at least with all your stash.....lolI’m so tired. The roof leaked in both bedrooms and then later at the chimney again. Roofer came Sunday to look things over. Can’t do anything about the chimney until snow and ice are gone but he thinks the peaked roof is fixed. I think the ridge cap isn’t right and any snow/ice or rain blowing sideways is getting in and melting later to leak.

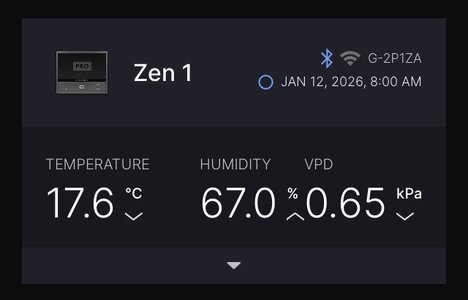

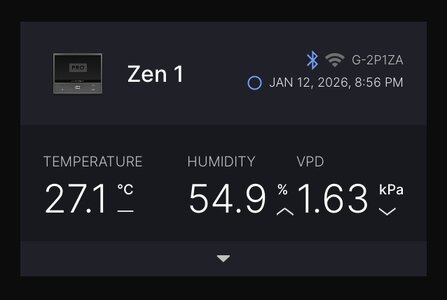

The dehumidifier is setup and being tested today. The old one was faster and held more water but this is a 50 pint/24 litre model. Guessing that’s about volume it can collect in a set time period and not how much the little bucket holds.

At one point yesterday afternoon it pissed all over the carpet floor. Not sure why but probably I hit the wrong button or maybe the pump button? We’ll see how todays test goes now that it’s setup. I put a try under the pumps hose port JIC.

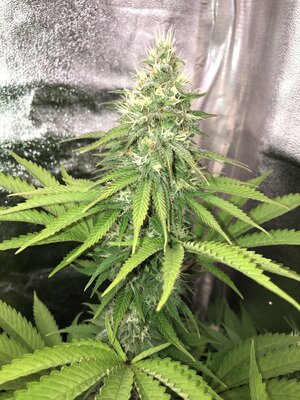

View attachment 123154View attachment 123155View attachment 123156

Rooms almost done. A couple pictures to hang. A few more things to put away and a final dusting and vacuuming after. The top of the tents were pretty bad for dust.

Before the dehumidifier.View attachment 123157

With the new dehumidifier.

View attachment 123158

Today will be the real test with everything closed and running from lights out to lights on.

Do you have a megger?I still haven't got my dryer working, I keep making fixes and blowing fuses after about 20 min, it doesn't make sense. There is no added load I have everything but the dryer shut off and it still blows a fuse. I may have to call in some help, fk there goes another few hundred$$ just to have someone show up.....

No, my 3#10 runs from the panel to the outlet with no breaks, none of the conductors are grounded all test good, Voltage is right. The top 2 fuses ( green) I moved the #10's from the fuse block below the ones they are in now thinking it may be a problem with the fuse block, one side still blows after changing location. All wires are tight.Do you have a megger?

They may not be grounded/shorted until enough amperage is being pushed through the lines. It's not directly shorted, but if the insulation is fucked in some spot, it could jump the gap when the load is increased. That's why I asked about a megger and not just a standard multimeter.none of the conductors are grounded all test good, Voltage

Its solid wire, and should be no reason for a resistance to build or wire to fail over 25-30ft. I've rung a megger in the past, we used to use them in the ship yard with stranded wires. Fun to give buddy's a blast with. I thought maybe the connectors at either end were crimping the wires but they aren't all that tight. It is the old clothe lumex/romex not plastic but solid wires with no breaks, no splices. I can see it all from panel to going through upstairs to the dryer. 30 amp is quite a load, I should see hot spots or smell something, I've pulled the receptacle and tested it, its good, no lose wires, no smell, no arcing, If I thought it was the wire I could easily swap it out but another couple hundred on a hope?. I'm thinking now my panel is fked, a poor connection between fuse and the bar, although its tight and this just started a few months ago.They may not be grounded/shorted until enough amperage is being pushed through the lines. It's not directly shorted, but if the insulation is fucked in some spot, it could jump the gap when the load is increased. That's why I asked about a megger and not just a standard multimeter.

How far is the run and how hard would it be to run a new line?

Won't necessarily see hotspots or anything like that if it's an insulation issue, which happens on overloaded circuits ran in old cloth wire quite frequently. Just enough of the insulation could be broken down internally, allowing it to jump the gap. Only a megger will tell you that.Its solid wire, and should be no reason for a resistance to build or wire to fail over 25-30ft. I've rung a megger in the past, we used to use them in the ship yard with stranded wires. Fun to give buddy's a blast with. I thought maybe the connectors at either end were crimping the wires but they aren't all that tight. It is the old clothe lumex/romex not plastic but solid wires with no breaks, no splices. I can see it all from panel to going through upstairs to the dryer. 30 amp is quite a load, I should see hot spots or smell something, I've pulled the receptacle and tested it, its good, no lose wires, no smell, no arcing, If I thought it was the wire I could easily swap it out but another couple hundred on a hope?. I'm thinking now my panel is fked, a poor connection between fuse and the bar, although its tight and this just started a few months ago.

I could buy a new 100amp service and swap it out too I may have to do that, add a few junction boxes to help with short wires but I could do it hot, without too much trouble, I'd have to do that in the summer though It would take me a day or two to complete it. I used to be able to swap them out in a few hours when I was all set up to do it. It might fk with my insurance though as I'm not really allowed to do that...I just keep sighing and hissing about it because I should have it figured out by now.

4 wire with ground...30 amp...have you ever cut or spliced a 30 amp line with load on it,big flash lots of arcing getting them back together.I would think with that kind of amperage I should see or smell some indication something is off, somewhere. If the receptacle is bad I should smell bakelite , There is no spark or noise to the fuse blow, dryer just stops heating drum still turns. dryer is only 5600 watts @240v 30 amp fuses should well cover that.Won't necessarily see hotspots or anything like that if it's an insulation issue, which happens on overloaded circuits ran in old cloth wire quite frequently. Just enough of the insulation could be broken down internally, allowing it to jump the gap. Only a megger will tell you that.

You said it's a new dryer, right? Is it ran off of a 3-wire cord or a 4-wire? If it's a 4-wire cord, did they still bond the neutral to the ground inside the dryer?

And inside the dryer, where the cord was hooked up... is the neutral and ground bonded? They shouldn't be for a 4-wire plug.4 wire with ground...30 amp...have you ever cut or spliced a 30 amp line with load on it,big flash lots of arcing getting them back together.I would think with that kind of amperage I should see or smell some indication something is off, somewhere. If the receptacle is bad I should smell bakelite , There is no spark or noise to the fuse blow, dryer just stops heating drum still turns. dryer is only 5600 watts @240v 30 amp fuses should well cover that.

I need to find a short 25/30 ft length.....2 or 3 /14 as a test run. With the 2 /14 I could still just use the ground for neutral...temporarily just to see if it is the wire...it doesn't really need a ground to run. I did notice the box the receptacle is in in not grounded. I normally wrap the ground around a screw in the box then pig tail to the receptacle.And inside the dryer, where the cord was hooked up... is the neutral and ground bonded? They shouldn't be for a 4-wire plug.

I get what you're saying about the arcs, but that's not always the case.

Swap out your whole panel for a couple hundred on just vibes, or run a new 30 foot run of 10/3 to rule that out. I know which one I would try first...

My only suggestion would be some WD40 on the shaft to get the fan blade spinning easier.Is the rubber gasket replaceable? . Fkin crack in your new dehue tank? That sucks, Can you use some crazy glue to fix the crack until you get a replacement ? I think its the same one I have, 50pint Danby, Black, mine works well. I now have 3 dehues each one a bit larger than the others. I should have gone with the 50 pint from the start but oh no I gotta be cheap and spend 3 X as much as I should have to get the job done.View attachment 123220

View attachment 123221

View attachment 123222

Anyone know if this motor can be fixed? My small engine/motor repair guy closed do to Covid. I’m 90% sure the old bearings are shot. The shaft over heats and the fan stops turning.

I still have a alternator guy a few blocks away, I think. Aren’t they close enough that he might have the parts to repair it? New things just aren’t made to last and only work half as well. If reasonable I’d like to get the motor fixed or replaced to deal with big jobs and use the new dehumidifier for day to day, once I get the new bucket.

I can’t remove the fan as the rubber washer that holds it on basically has dried out and bonded to the shaft. It makes a square hole in the fan attach to a round shaft. If I try to take it off if will destroy the rubber and I’ll be screwed.

This is a deal with it later project I’m just wondering if anyone else has knowledge or experience with this.

I was an electrical estimator not an electrician. I can fix most things with common sense and access to parts but this goes way back. Pretty sure I’m out of luck finding 45 year old parts.

You can likely find a replacement motor online but that doesn't fix you lr fan problem...If reasonable I’d like to get the motor fixed or replaced

Like Pipe said, you can probably find a replacement bushing for the fan-to-shaft connection but I wonder if you could print one.If I try to take it off if will destroy the rubber and I’ll be screwed.

I used 3-1 penetrating oil. Worked for a day.My only suggestion would be some WD40 on the shaft to get the fan blade spinning easier.

Yes and no. It has a hose clamp on it to hold it in place. But it’s the old rubber. It’s hard now and bonded to the metal shaft. When I get a few things off my plate I’ll remove the motor and open it up. Pretty sure I’ll need to remove the fan before it can come apart but I’ll worry about that later.Is the rubber gasket replaceable?

I got it at Princess Auto on the 12th. It was a refurb. Worked fine until the leak. I hooked up the gravity drain to a short hose section I had and it ran like that all night. Seems good.Fkin crack in your new dehue tank? That sucks, Can you use some crazy glue to fix the crack until you get a replacement ? I think its the same one I have, 50pint Danby, Black, mine works well. I now have 3 dehues each one a bit larger than the others. I should have gone with the 50 pint from the start but oh no I gotta be cheap and spend 3 X as much as I should have to get the job done.

The aluminum fan has a square hole rather than round. I’m guessing this rubber acted like a torque dampener. Never seen one before. I’ll take pics later when I get time. A quick check has me thinking the fan needs to come off so the top of the motor casing can slide off. Not sure ATM.You can likely find a replacement motor online but that doesn't fix you lr fan problem...

Like Pipe said, you can probably find a replacement bushing for the fan-to-shaft connection but I wonder if you could print one.

Cool. I’ll have a search. Not cheap is a concern. Wonder why?I googled this "electrohome motor 2868-407-089 CLB" and found plenty of results... not cheap. Just verify all the info on the labels before purchasing.

Yes but it is a penetrating oil and will lubricate the shaft to help it spin.There are better penetrating oils but WD is usually handy, we all have a can or 2 around.....Don't we?BTW, WD40 isn’t a great lubricant like our generation was told. It’s to remove water. WD40 stands for water displacement 40th test.

I'm still stumped,I've tried a bunch of fixes but nothing works for long. I may have to replace the wire but I don't think that's the issue either. Clothes are drying all over the inside of our home. Or on the line outside...not ideal in the winter.I used 3-1 penetrating oil. Worked for a day.

Yes and no. It has a hose clamp on it to hold it in place. But it’s the old rubber. It’s hard now and bonded to the metal shaft. When I get a few things off my plate I’ll remove the motor and open it up. Pretty sure I’ll need to remove the fan before it can come apart but I’ll worry about that later.

I got it at Princess Auto on the 12th. It was a refurb. Worked fine until the leak. I hooked up the gravity drain to a short hose section I had and it ran like that all night. Seems good.

I was able to get there at 7am this morning and told them I’ll either buy the other unit and return it after I swap the tub/bucket or you can let me swap it without the added work. They let me swap it but took my receipt and noted it as a return. So far so good. We’ll see by this afternoon.

The new ones are quieter but take all day to do what the old one would do in a couple hours. I want to keep the old one as it’s all metal and made to last. I just clean it yearly or as I see dog hair and dust collect on the back. No filter on it. I’m willing to bet it’s just an original sealed baring. Not sure if it’s repairable or I need a new motor.

It was mostly used for drying rooms out after a flood. The family used to pass it around over the years as needed. I’m the last.

How’s your dryer adventures going? I’ve been reading following without logging in. It sucks when you’re troubleshooting and nothings found to be wrong but the issue keeps occurring.

Any chance it’s the actual fuse block? Worn or a lose connection that’s causing it to blow after a load?

I’m a little newer panel than yours. Stablock breakers.