- Joined

- Apr 16, 2023

- Messages

- 4,239

- Reaction score

- 19,305

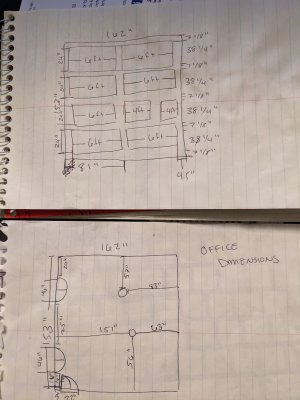

Should be good depending on the required rating. 1/2" sheetrock has a 30 minute rating but they also make fire caulk and fire puddy. They might even sell fire foam in a can. In you're case, depending on the size of your hole, you could just fill it with mud.Scratch that, figured out a more optimal path that doesn't require crossing water pipes nor electrical. only four holes deep so fargood thing i'm good with drywall and texturing haha.

but i do have another question regarding fire blocking.

the penetration I'm making from the utility room to the stairwell is at a similar height to a penetration the home inspector listed as needing fire blocking. Given I don't want to leave an undressed hole in the wall -- it'll bug tf out of me every time I'm in the room -- I figured I could take some sheet rock and box in the penetration prior to running the wire. Would that be good enough or do I need to figure out something more extensive like filling the gap around the penetration with fire blocking spray foam?

A lot of our commercial penetrations just end up mudded. It's only the larger gaps that get the putty or caulk. Even around special fire rated sleeves, mud.