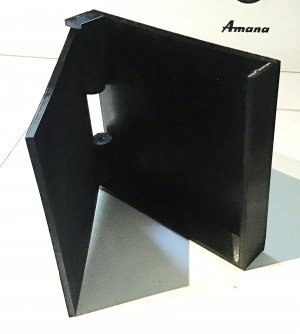

NICE~!

Love buy back loyalty nug smasher has.

I look at like a buying a fine diamond.

I love the 4X6 plates.

You'll squish a ton with that.

The Touch had me at "Extraction Brain"

4"x6" plates will have me spoiled too.

Looks like this is gonna happen. They opened the ticket and I sent them pics then I got a call and email back.

Also found a better code than their blackfriday code. Instead of 12% off with that one, code 15OFF is worth 15% off.

So the way this works best is when they have a sale like this BF or the 15 off.

You have two options...

Buy the new press now with the sale code then send the old unit back and they'll refund that 80% trade in value to your card.

The next option is to send the old press back now and wait for the new discount code for your trade in then buy the new press.

However you can only use one code at a time and if you use the buy now pay later financing the refund come in the value of store credit.

I took the first option buying the new press first with a sale code then will wait for a refund to my card later after I send the old unit back. That's the only to get both trade in value and a coupon to work together.

Before the price slash sale this was a $4000 press. After the slash it's a $2400 press. After the coupon and trade in, my out of pocket cost is $1581

I probably could've got the XP for $400-$500 out of pocket and been happy but dang..A $4000 12 ton digital w/ 4"x6" plates for under $1600 is just too good to pass up!

So yep...she's mine!!!!

Ill give ya 450 for it

lol jk my wife would kill me.

I cant touch a nugsmasher for what they cost lol. I was looking at a dabpress brand a while back tho lol.

Nugsmashers buyback program does look like a good deal tho.

I just told my wife thanks for such an awesome Xmas gift she doesn't know she bought me yet.

Yep the buyback program and lifetime warranty is considerable in this choice. If not for that warranty, I doubt I woulda gone for the digital upgrade.

These things are already built like tanks but I'm always skeptical of electronics and heat so that warranty gives me piece of mind.

And the folks at NS are incredibly ez to work and communicate with.